you’re reaching for your favorite glass, the one that holds just the right amount of iced coffee, and—crash—it slips, shatters, and now you’re sweeping up the pieces, muttering about your clumsiness. We’ve all been there. But what if, instead of cursing your butterfingers or scouring stores for a replacement, you could just print a new glass? Yeah, you heard me right—3-D-print one, right in your kitchen.

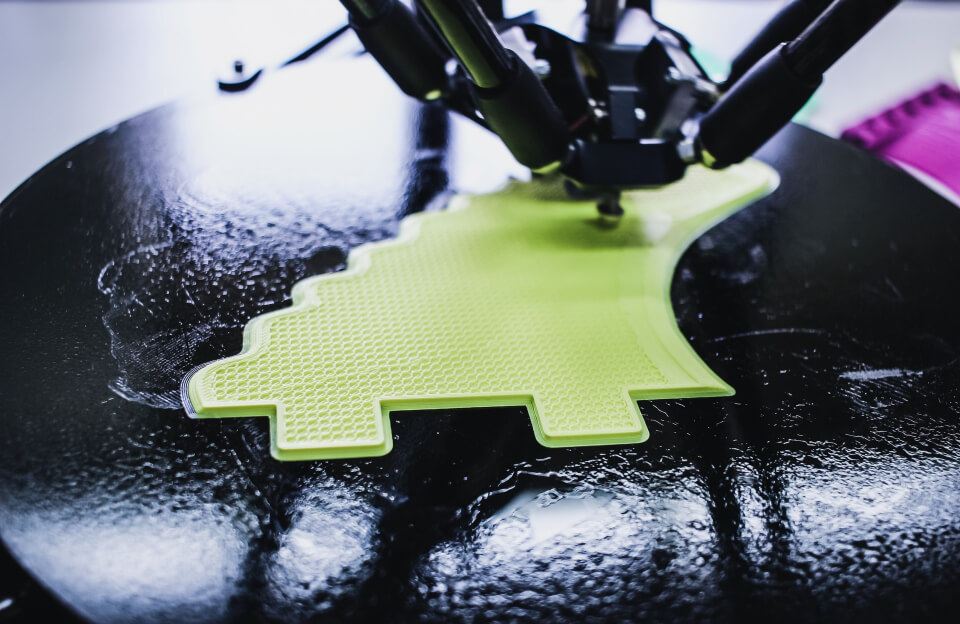

It sounds like something straight out of a sci-fi flick, but 3-D printing technology is inching closer to making this a reality. These days, 3-D printers can already churn out everything from plastic toys to intricate metal parts for rockets. So, why not glass? Turns out, researchers and innovators are already on it, figuring out how to take the same tech that builds plastic knickknacks and turn it into a way to craft sleek, durable glassware.

Here’s the deal: glass is tricky. It’s not like plastic that you can just melt and squirt out of a nozzle. Glass needs crazy-high temperatures—think over 2,000°F—to get all melty and moldable. But scientists have been tinkering with ways to make it work. Some are using special printers that heat silica (the main ingredient in glass) with lasers, layering it bit by bit to form shapes. Others are experimenting with pre-made glass powders or even recycled glass bits, turning old wine bottles into new vases. Cool, right?

The best part? This isn’t just about replacing your broken tumbler. Imagine customizing your glassware on the fly—want a mug with your name etched into it or a funky geometric wine glass for your next dinner party? Just download a design, hit print, and boom, you’re a glassware designer. Plus, it could be a game-changer for sustainability. Instead of shipping heavy glass across the globe, you could recycle shards from your recycling bin and print something new, cutting down on waste and energy.

Now, don’t get too excited just yet. We’re not quite at the point where every home has a glass-printing machine next to the microwave. The tech is still pricey, and the process is slow for now—think hours to print a single glass. Oh, and those high-temp printers? They’re not exactly countertop-friendly. But the pace of innovation is wild. Just a decade ago, 3-D printing was barely a thing outside of tech labs, and now you can buy a decent printer for a few hundred bucks. Give it a few years, and who knows? Your next broken glass might not be a tragedy—it might just be an excuse to fire up the printer.

So, the next time you drop a glass and wince at the mess, just smile and think: someday, you might be printing a new one, no sweat. Until then, maybe stick to plastic cups for a while.